| Items |

3070-FMS

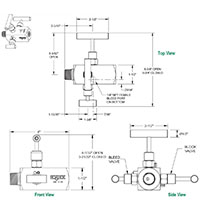

1/2" National Pipe Thread (NPT), Female x Male, 316 Stainless Steel, Hard Seat, 0.187" Orifice Double Block and Bleed 3-Valve

|

3070-MFC

1/2" National Pipe Thread (NPT), Male x Female, Steel, Hard Seat, 0.187" Orifice Double Block and Bleed 3-Valve

|

3070-MFS

1/2" National Pipe Thread (NPT), Male x Female, 316 Stainless Steel, Hard Seat, 0.187" Orifice Double Block and Bleed 3-Valve

|

3072-MFC

1/4" National Pipe Thread (NPT), Male x Female, Steel, Hard Seat, 0.187" Orifice Double Block and Bleed 3-Valve

|

3072-MFS

1/4" National Pipe Thread (NPT), Male x Female, 316 Stainless Steel, Hard Seat, 0.187" Orifice Double Block and Bleed 3-Valve

|

|

Description

|

N/A

- Combines isolating and venting in a single valve, eliminating the need for tubing and fittings

- Block valve isolates the downstream process fluids, and the bleed valve exhausts upstream fluids enabling instruments to be removed without disturbing the permanent piping installation on the bottom

- The 1/4" NPT vent plug is located 90º to the left and may be removed and replaced with exhaust piping to direct the fluids to a safe location

|

|

Type

|

N/A

Needle Valve

|

|

Series

|

N/A

3070

|

|

Material

|

N/A

Electropolished 316 Stainless Steel

|

N/A

Zinc-Nickel Plated Steel

|

N/A

Electropolished 316 Stainless Steel

|

N/A

Zinc-Nickel Plated Steel

|

N/A

Electropolished 316 Stainless Steel

|

|

Stem Seal and Type

|

N/A

All 316 Stainless Steel stems with Fluorocarbon (FKM) o-ring and Polytetrafluoroethylene (PTFE) back-up ring below the threads, Polytetrafluoroethylene (PTFE) or Graphite packing optional

|

|

Pressure Ratings at 200 Degree Fahrenheit (ºF) Temperature

|

N/A

10,000 psi

|

|

Weight

|

N/A

3.2 lb

|

|

Orifice Size

|

N/A

0.187 in

|

|

Cv Coefficient

|

N/A

0.44

|

|

Connection Size

|

N/A

1/2 in

|

N/A

1/2 in

|

N/A

1/2 in

|

N/A

1/4 in

|

N/A

1/4 in

|

|

Seat

|

N/A

Hard Seat

|

|

Valve Type

|

N/A

Female-Male

|

N/A

Male-Female

|

N/A

Male-Female

|

N/A

Male-Female

|

N/A

Male-Female

|

|

Valve Material

|

N/A

Stainless Steel

|

N/A

Steel

|

N/A

Stainless Steel

|

N/A

Steel

|

N/A

Stainless Steel

|

|

Process Type

|

N/A

3-Valve Block and Bleed

|

|

Warranty

|

N/A

3 y

|

|

Length

|

N/A

4 in

|

|

Extended Length

|

N/A

5-3/8 in

|

|

Connection Type

|

N/A

National Pipe Thread (NPT)

|

|

End Size

|

N/A

1/2

|

N/A

1/2

|

N/A

1/2

|

N/A

1/4

|

N/A

1/4

|

|

Prop 65 Warnings

|

N/A

WARNING: WARNING: This product can expose you to chemicals including Lead and Nickel, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

|

|

Additional Options

|

N/A

- Packings

- Stem Tips

- Non-rotating (316 stainless) (T1 )

- Ball (440C stainless) (T5)

- Ball (carbide) (T6)

- Ball (Monel) (T8)

- Non-rotating regulating (316 Stainless) (T9)

- O-Rings

- EPDM (EM1)

- FFKM (Perfluoroelastomer 3018 or equivalent) (KZ1)

- NBR (NB1)

- Handles

- 1-13/16" Mini "T" (HL1)

- 2-1/2" "T" (HL2)

- 1" Round knurled (H3)

- 1-3/8" Phenolic (HL4)

- 1-3/4" Phenolic (HL5 )

|

|

Additional Information

|

N/A

- 100% helium leak tested to 1 x 10-4 ml/s for guaranteed performance and reliability

- Blow-out proof stem provides a secondary stem seal in the full open position

- FKM o-ring seal and PTFE back-up ring below the stem threads to protect from corrosion and galling; PTFE or Graphite packing optional

- All stem threads are rolled for strength and ease of operation

- One-piece bonnet with a metal-to-metal seal to the valve body below the bonnet threads

- Slotted spring pin to prevent accidental loosening

- Vinyl dust cap for bonnet and stem (non-packing)

|

|

Installed Options and Accessories

|

N/A

- Packing (If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the Pressure vs. Temperature: Packing Style with Compatible Fluid chart Options Reference Chart)

- Stem Tips

- Non-rotating (316 Stainless Steel) (T1)

- Ball, 440C Stainless Steel (T5)

- Ball, carbide (T6)

- Ball, ceramic (T7)

- Ball, Monel (T8)

- Non-rotating regulating, 316 Stainless Steel (T9)

- O-Rings (Other o-ring materials available on request)

- EPDM (EM1)

- FFKM (Perfluoroelastomer) 3018 or equivalent (KZ1)

- NBR (NB1)

- Panel Mount

- Handles

- 1-13/16" Mini T-Handle (HL1)

- 2-1/2" T-Handle (HL2)

- 1" Round Knurled Handle (HL3)

- 1-3/8" Phenolic Handle (HL4)

- 1-3/4" Phenolic Handle (HL5)

- Cleaning For Oxygen Service (Stainless Steel Only)

|

|

Assembly Options

|

N/A

NOSHOK offers multiple assembly options to meet your specific system requirements. Consult factory to discuss your customized solution.

|

|

Note

|

N/A

Packings - If a packing option is chosen, maximum pressure rating is 6,000 psi. Refer to the "Pressure vs Temperature: Packing Style with Compatible Fluid" chart.

O-Rings - Other o-ring materials available on request.

Please note that the standard o-ring in all the NOSHOK valves is FKM and the standard handles are block "T" handles (HL2) and bleed 1-3/8" mini "T" handle (HL7).

The handle material will always match the material of the valve, unless otherwise specified. For example, the "T" handle (HL2) on the 3070-FFC will be steel. When only the standard configuration is needed, no additional designations are necessary. Please consult the factory for special application requests.

All NOSHOK valve products conform to the MSS SP-99 instrument valves standards, and valves supplied with packing also conform to MSS SP-132 compression packing systems for instrument valves standard.

|

WARNING: This product can expose you to chemicals including Lead and Nickel, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to

WARNING: This product can expose you to chemicals including Lead and Nickel, which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to