| Items |

H2-1A23A3J4111

HPR-2 0 to 500 Pounds per Square Inch Gauge (psig) Outlet Range and 0.06 Flow Coefficient (Cv) Electrically Heated Single Stage Vaporizing Regulator

|

H2-1A33H3G311

HPR-2 0 to 100 Pounds per Square Inch Gauge (psig) Outlet Range and 0.06 Flow Coefficient (Cv) Electrically Heated Single Stage Vaporizing Regulator

|

H2-1A33H3G411

HPR-2 0 to 100 Pounds per Square Inch Gauge (psig) Outlet Range and 0.06 Flow Coefficient (Cv) Electrically Heated Single Stage Vaporizing Regulator

|

H2-1A55H3G111

HPR-2 0 to 100 Pounds per Square Inch Gauge (psig) Outlet Range and 0.06 Flow Coefficient (Cv) Electrically Heated Single Stage Vaporizing Regulator

|

H2-1C22B3J411

HPR-2 0 to 500 Pounds per Square Inch Gauge (psig) Outlet Range and 0.06 Flow Coefficient (Cv) Electrically Heated Single Stage Vaporizing Regulator

|

|

Description

|

N/A

The HPR-2 Series heated pressure regulator is designed to supply heat to samples entering instrumentation systems. It can be used to preheat liquids, to prevent condensation of gases or to vaporize liquids prior to gas analysis.

The modular design of the HPR-2 consists of heat exchanger and pressure control sections. The pressure control section is patterned after the time proven design of the PR-1 pressure reducing regulator and provides the same excellent outlet pressure stability. The heat exchanger section is made up of a body and heat exchange element. The heat exchange element uses GO Regulator's unique spiral wrapped screen as the heat exchange surface. This screen has up to 100 square inches of heat transfer area and precise design forces all sample flow to pass through the element.

The HPR-2 Series of vaporizing pressure reducing regulators are both CSA and ATEX approved. The electrical components of this unit are securely housed in a Class A, B, C, D condulet assuring that there is always an adequate flame path between the environment and the controller. Safety considerations can be further enhanced by using the optional TCO (Thermal Cut Out) heater cartridge. This feature enables the unit to boast a T3 rating with up to 250 watts of power (250w is rated T2C for CSA).

|

|

Brands

|

N/A

GO Regulator, Inc.

|

|

Body Material

|

N/A

316L Stainless Steel

|

|

Port Configuration

|

N/A

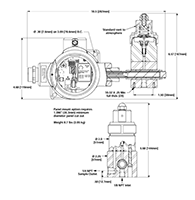

A - See Diagram for Port Configuration

|

N/A

A - See Diagram for Port Configuration

|

N/A

A - See Diagram for Port Configuration

|

N/A

A - See Diagram for Port Configuration

|

N/A

C - See Diagram for Port Configuration

|

|

Temperature Range/Heating Type

|

N/A

24 to 80 ºC75 to 175 ºF

|

N/A

54 to 149 ºC130 to 300 ºF

|

N/A

54 to 149 ºC130 to 300 ºF

|

N/A

|

N/A

75 to 175 ºF

|

|

Heater Wattage

|

N/A

100 W

|

N/A

100 W

|

N/A

100 W

|

N/A

|

N/A

50 W

|

|

Seat Material

|

N/A

Tefzel®

|

N/A

Polychlorotrifluoroethylene (PCTFE)

|

N/A

Polychlorotrifluoroethylene (PCTFE)

|

N/A

Polychlorotrifluoroethylene (PCTFE)

|

N/A

Ceramic Filled Polytetrafluoroethylene (PTFE)

|

|

Flow Coefficient (Cv)

|

N/A

0.06

|

|

Outlet Range

|

N/A

0 to 500 psig

|

N/A

0 to 100 psig

|

N/A

0 to 100 psig

|

N/A

0 to 100 psig

|

N/A

0 to 500 psig

|

|

Heater Block Type

|

N/A

230 V Alternating Current Voltage (VAC)

|

N/A

120 V Alternating Current Voltage (VAC)

|

N/A

230 V Alternating Current Voltage (VAC)

|

N/A

|

N/A

230 V Alternating Current Voltage (VAC)

|

|

Heater Block Porting

|

N/A

Standard Block

|

|

Cap Assembly

|

N/A

Tamper-Proof, Standard, Stainless Steel

|

|

Options

|

N/A

TCO Thermistor

|

N/A

|

N/A

|

N/A

|

N/A

|

|

Options (Not Required)

|

N/A

|

|

Inlet Pressure

|

N/A

Up to 6000 psig at 380 ºF (193 ºC)

|

|

Operating Temperature

|

N/A

Up to 500 ºF260 ºC

|

|

Certifications

|

N/A

Atmospheres Explosibles (ATEX) Directive 2014/34/EU Canadian Standards Association (CSA) Certification # LR-82566-5 Certification # TRL03ATEX11001X

|

N/A

Canadian Standards Association (CSA) Certification # LR-82566-5 Certification # TRL03ATEX11001X

|

N/A

Canadian Standards Association (CSA) Certification # LR-82566-5 Certification # TRL03ATEX11001X

|

N/A

Canadian Standards Association (CSA) Certification # LR-82566-5 Certification # TRL03ATEX11001X

|

N/A

Canadian Standards Association (CSA) Certification # LR-82566-5 Certification # TRL03ATEX11001X

|

|

Typical Applications

|

N/A

Analytical process sample conditioning systems:- Petrochemical refineries

- Chemical production facilities

- Pilot plants (chemical & petrochemical)

- LNG loading and off-loading points

- Natural gas pipeline sampling

|

|

Features and Benefits

|

N/A

- Optional HASTELLOY® C and MONEL®

- Electropolished body with better than 25 Rafinish in diaphragm cavity for an optimal sealing surface

- Bubble-tight shutoff

- Modular pressure control and heat exchanger assemblies for easy maintenance

- Unique spiral wrapped heat exchange element provides up to 100 square inches of heat transfer area.

- Optional TCO heating cartridge

- INCONEL® diaphragm standard

|

|

Note

|

N/A

- Contact the factory for any additional requirements.

- Units that will be used for flammable liquid or gas with fire point at 200ºC or below require the TCO Thermistor. It is also recommended to use the 1-PC body option. In addition, Tefzel and PCTFE seats in these units are recommended to use the captured vent cap option which provides for venting to a safe location.

|